So at long last, I took and passed my long threatened ETCP theatrical rigging certification.

My score was 126 out of 150. Passing was 104. It was all graded on some weird sliding weight scale that I was going to write about – but I don’t care now. I passed. Rejoice and settle wagers accordingly.

All of those standardized tests I took in school turned out to be of some value. (That’s right millennials, standardized testing is not a curse aimed specifically at your generation.) Over 165 questions (of which only 150 are graded – but they’ll never say which) I got to use every one of those sneaky little strategies I learned in grade school.

But what really, really helps, and there is no avoiding this, is knowing what you are doing. Here experience in installing as well as operating systems in multiple venues was invaluable.

Also, I studied.

These were indeed the textbooks I relied on – in order of value:

- Stage Rigging Handbook (3rd Edition) by Jay O. Glerum. This is THE textbook for operating fly system as an adult who gets paid for it.

- Rigging Math Made Simple by Delbert L Hall. The link is to the 3rd edition, but the copy I have is the second edition.

- Entertainment Rigging by Harry Donovan. This is more aimed at arena rigging, but the approach to working load limits is more detailed.

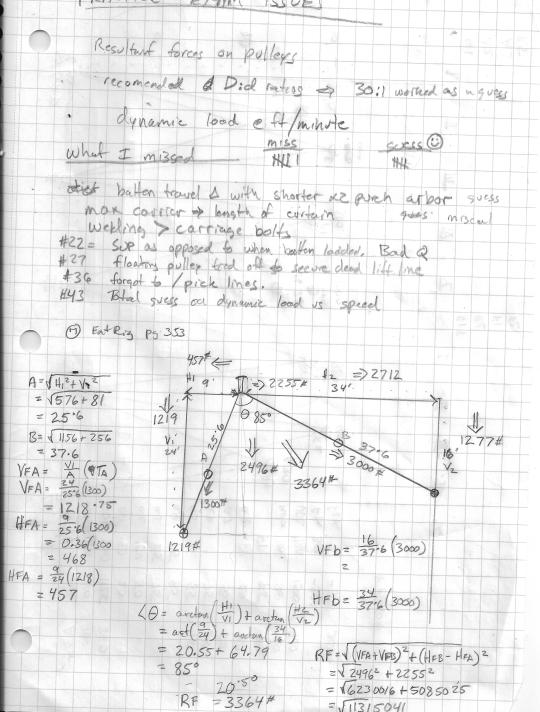

There were a LOT of questions about components of counterweight rigging systems and their use – as one would expect. There were also a LOT of questions about Working Load Limit, as related to Ultimate Breaking Strength and how to calculate one from the other. It is further crucial to understand what resultant force is and how to calculate it.

If in doubt, the weak part in the system is the cable clips. Somebody writing questions had a grudge against cable clips.

Other useful tidbits from my notes:

A useful, basic math tutorial we found while researching the electrician side:

https://www.mikeholt.com/instructor2/img/product/pdf/1302643781-sample.pdf

I like this advice in particular:

When working with any mathematical calculation, don’t just blindly do the calculation and assume it’s correct. When you perform a mathematical calculation, you need to know if the answer is greater than or less than the values given in the problem. Always do a “reality check” to be certain that your answer isn’t nonsense. Even the best of us make mistakes at times, so always examine your answer to make sure it makes sense!

A good, concise (if dry) guide to wire rope and things attached to it:

http://energy.gov/sites/prod/files/2013/09/f2/std1090-07_chapter_11_wire_ropes_and_slings.pdf

Breaking strength

The measured force required to actually break the thing. This can only be properly measured by testing, eg applying force until it actually breaks, and writing that number down.

The best source for this information is the manufacturer. Manufacturers of actual rigging equipment will test a large sample of their items to determine a breaking strength (which is most cases is really a bell curve; the number given is in the center of that curve), and provide that number to the customers – somehow.

That number is the basis for all the other load limit calculations, and why we prefer – nay insist upon – manufactured gear with known breaking strengths to rig with.

IF YOU CANNOT DETERMINE THE ACTUAL BREAKING STRENGTH – YOU SHOULD NOT USE THE EQUIPMENT.

Breaking strength is an average for most components, and only applies to new equipment. You must assume used equipment to have a lower BS and downgrade accordingly.

[…]

Working Load Limit is the fraction of the known breaking strength used in determining how much we will say the equipment is rated for. We then treat that like it’s a real limit and not a number that we derived from a much higher number that is actually an average of measured results. The specific point of a professional rigger is that WLL’s are rational and enforced.

When riggers say a chain is only as strong as its weakest link, they are not speaking metaphorically. That is the literal truth with rigging systems: the lowest WLL of any component (which could literally be chain) in a system determines the WLLL for that entire system.

and one more:

Fleet angle

In a perfect world, all of the lift lines would run true from their head-block and across the loft blocks in a perfect, straight line. The difference between that and what is actually installed is called the fleet angle. It is measured from the center of the sheeves.

The maximum allowable fleet angle for theatrical rigging is 1.5 d.

Fleet angle can be determined by finding the Tangent of the offset distance divided by the distance between shivs. (Be sure to use the same units of measure). [Glerum 102]

As a quick gauge, an offset/distance ration of 1:40 or greater is going to pass. An offset of 1:30 or less is going to fail. Between 30 and 40, you’ll have to do the math.

For those who got this far, I admire your dedication. Do the work – that’s what we learned.